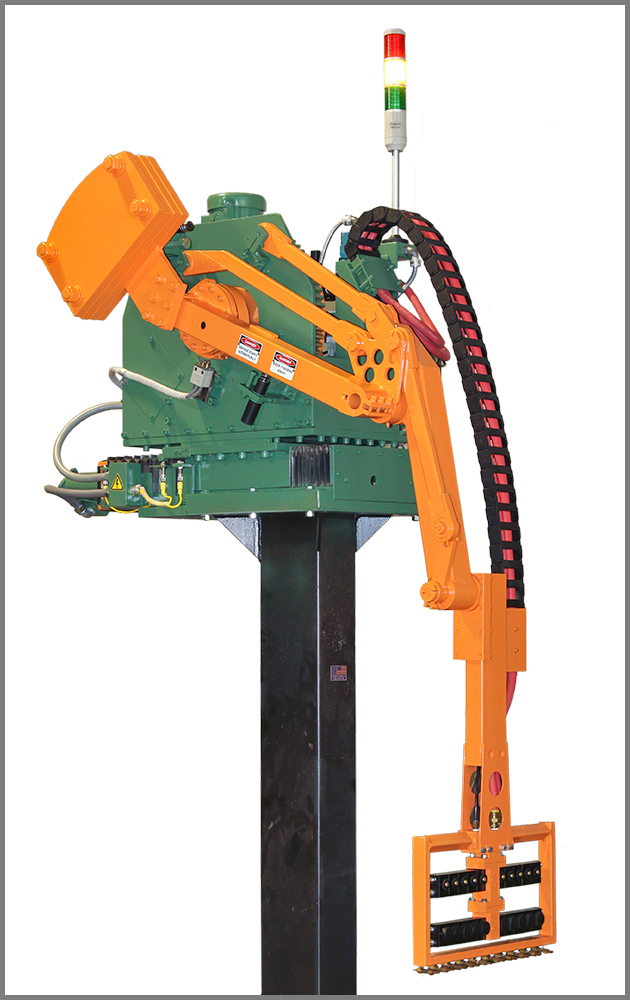

Snair can provide automation solutions with dynamic pedestal systems for ladlers, parts extraction, die spraying, and conveying equipment. These components can be purchased and installed separately to allow further automation over time.

The 803 and 896 lines of high speed, heavy duty parts extractors provide straight-line movement into and out of high pressure horizontal die casting machines. The linkage design universal to Snair equipment produces a very rigid and compact framework while requiring minimal power.

Snair also offers the SV line of vertically reciprocating spraying equipment. The linkage design provides highly reliable performance as there are no chains to adjust and no cylinders to maintain. The linkage system also allows the arms to fold back away from the parting line to minimize the build up of material on the equipment and to facilitate access and maintenance of the dies.

Parts cooling can be provided in several forms. The solid plate steel version offers heavy duty performance for either indexing or continuous movement applications. High efficiency, high capacity air cooling tunnels can be added in a variety of configurations to provide directional forced air to cool the cast parts.

Rely on Snair to improve productivity by reducing material handling, streamlining production, and minimizing scrap.